Tim's Tips

Chain Tooth Parts

Tim's Tips Chain Tooth Parts |

|

| Smooth and efficient cutting of the saw requires a

properly sharpened chain. Many chain saw operators tend to reduce the height of the rakers

in an attempt to "take a bigger bite". Although this feels like the saw is

grabbing more wood, it is putting a great deal of strain on the chain, sprocket and drive

mechanism. It also reduces cutting speed and increases the chance of injury to the

operator. To properly file a saw, it is important to understand the function of each of

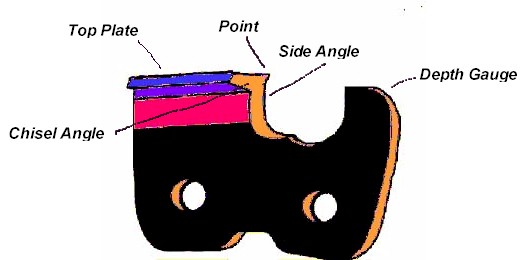

the elements of the saw chain: 1. Raker (also known as the depth gauge or drag) - The raker determines the thickness of the chip. This should be 20 to 30/1000 of an inch depending on whether you are cutting hard wood or soft wood. A raker depth gauge is the best tool to use to get the proper height of the raker. These can be purchased from local chain saw dealers. 2. Point or Working Corner - This is the point formed by the intersection of the side and top plates. This is where the cut begins. 3. Side Plate - This cuts off the fiber. The side plate should be perpendicular (90 degrees) to the base of the tooth. Many chain saw operators have a tendency to create a hook on the side plate. Creating an angle that is too great will cause the tooth to be sucked into the wood creating a kickback danger. This is very dangerous and inefficient. 4. Top Plate - The top plate angle establishes the width of the saw kerf. The angle causes the tooth to be pushed to the side. The greater the angle, the more wood needs to be cut. Today's saws need a top angle of 20-35 degrees. 5. Chisel Angle - This angle, which is beneath the top plate, allows chips to slide underneath the tooth. This angle should be 45 to 55 degrees. |